Great news Joe! Now you should be able to enjoy this latest tour....

Well, it has been awhile since the last tour, mostly because of difficulty with the PC which ended with erasing my entire ten-year history of photos taken with my camera. I'm also dealing with an unknown condition that has made driving for me too dangerous. At least I still have my hobby and now my PC is fixed enough to be able to start some more tours.

All aboard the trams, we will be departing soon for the Hangar....

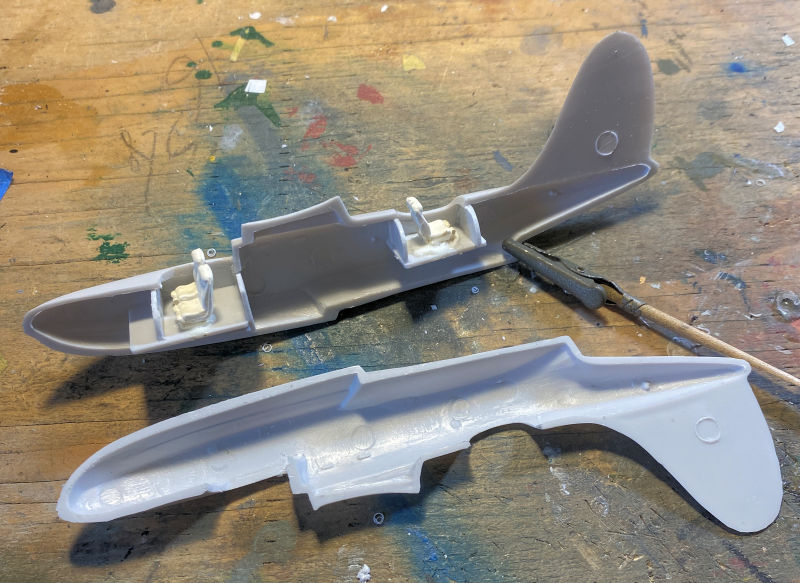

Here in the Hangar, there has been only one project that we worked on, but a serious amount of work was done on it. This is a simple yet difficult kit from RPM; a very short run kit that I decided to start just to get it off the stash. It is a Russian Be-4 float plane, and the instructions had us start on the engine and cowling. After some intensive sanding, test fitting and sanding again, thwe engine finally sat in place correctly. There are no attachment points or guides for any of these parts:

Next we started on the "highly detailed cockpit". That consisted of adding the pilot seats to the main floor...that's it. Only they wanted us to place the seat bottom first and then 'scratch build' the seat backs! Forget that... I went straight to my parts box and added these seats instead:

Next the bulkheads went in place. They took a bit of finagling, as again; there's no guides or attachment points to put them in their proper place:

Finally, the "interiors" were added; I happen to find a third seat for the gunner/radio operator's station that matched the two pilot seats. You can see in this pic how the floors and bulkheads will need to be trimmed and sanded before the fuselage will close:

After a test fit, we moved the seats back:

After some snipping, sanding, test fitting, adjusting, readjusting, we finally got the fuselage together. It went together better than expected for such a short run kit:

There were still some seams and steps to deal with so out came Mr. Surfacer 500:

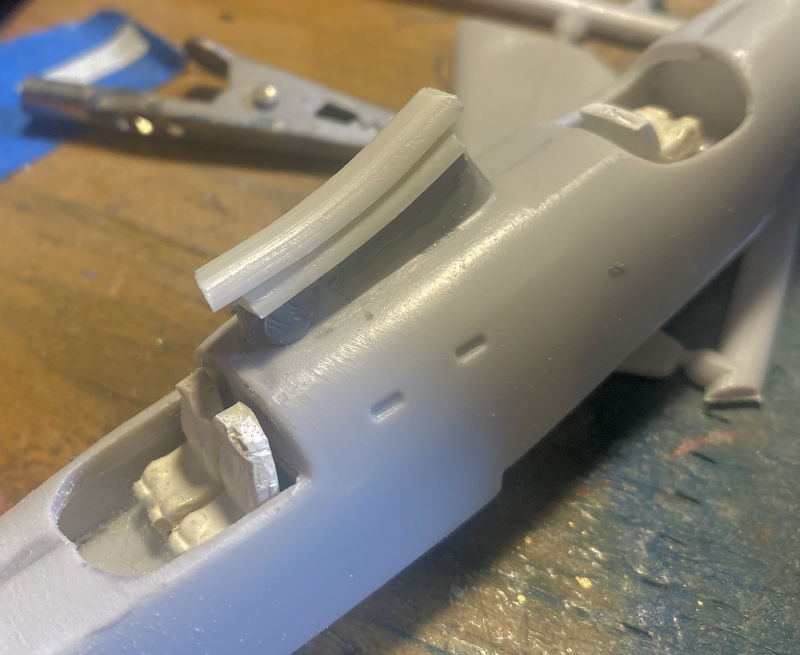

After test fitting the gunner's dome, I realized that seat needed to be trimmed so we got that trimmed down to fit:

Another test fit later; this time of the wing, we noticed that the pylon was too short and that the propeller would cut off the nose of the plane so an adjustment had to be made. We took some sprue from the kit; cut it to length, bent it a bit and then glued them into place:

Some judicious trimming and sanding later and the pylon is ready to take the wing and the propeller will be able to spin freely:

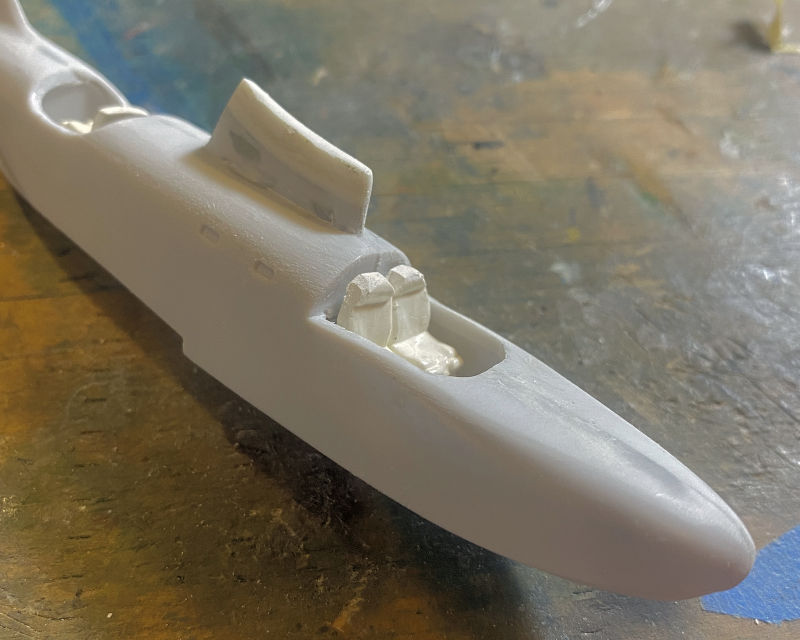

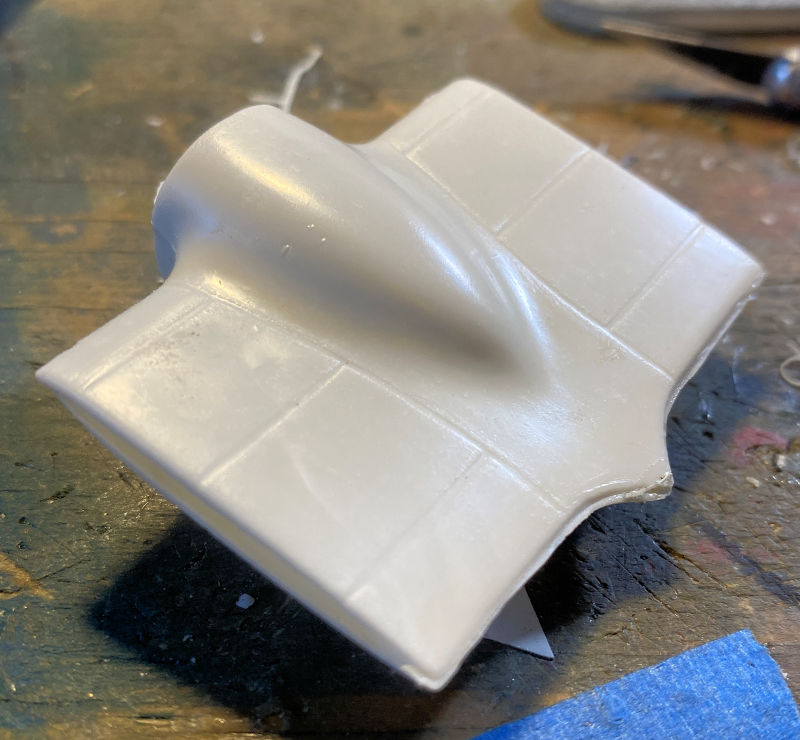

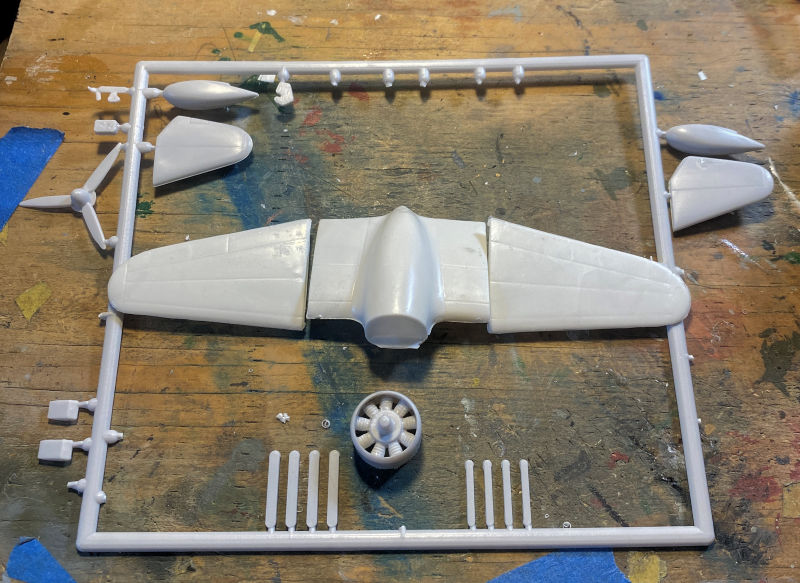

Speaking of the wing, it came in six parts. the center section is here:

The two outer halves on each side needed to be cemented together as well. We did this along with cementing all the outrigger floats and the tail plane halves together as well:

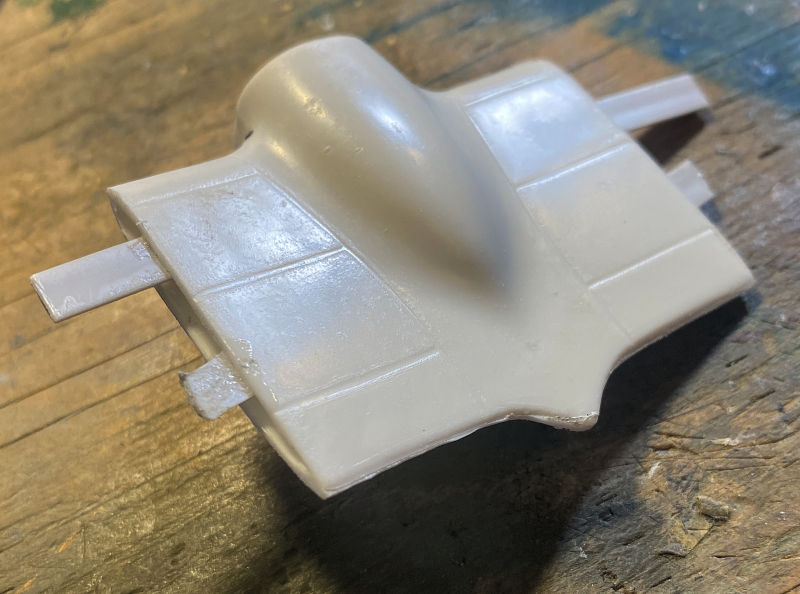

This poor molding leaves us with a butt joint that would break if you looked at it wrong:

Well, if they were not giving us a proper way to cement this together in any manner that would hold, we added some sprue runners that the end parts would be able to grip:

Here is the first attempt to glue the ends of the wing to the center:

You can see how poor fitting these are, worse than the fuselage. So, further adjustments were made...

...and made....

And since I still wasn't satisfied we took them apart and re-started them, hopefully finally getting the wing to look right. Pics of that forthcoming later during a follow on tour..

Meanwhile, the pylons were added to the outrigger floats:

You can see where we had to fill some holes where the pontoons themselves were short shot. They are ready for installation one the wing turns out satisfactory enough.

While waiting for the latest adjustment on the wing to take, we painted the interiors:

When test fitting the main canopy, we found it was too short to cover the whole cockpit opening, so we trimmed a piece of black sheet styrene to shape and added it to the front of the cockpit opening:

The results look much better and will look even better under paint:

Well, that completes the latest work in the Hangar, let's move on to the Motor Pool...

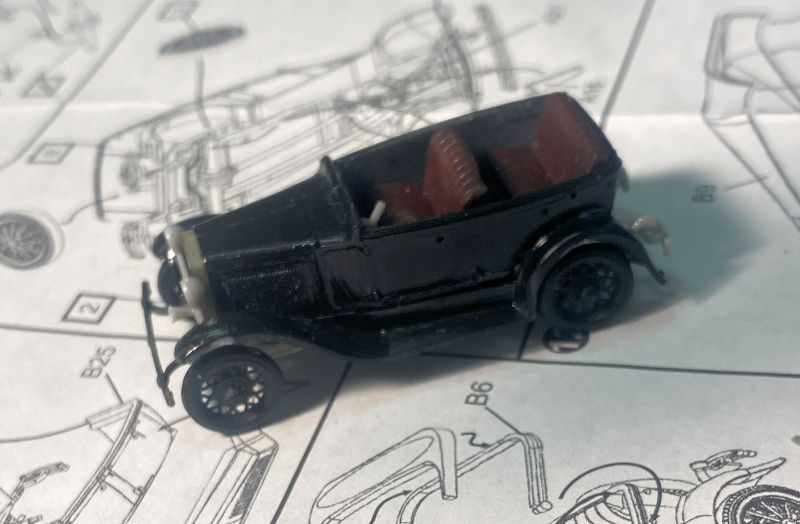

Here in the Motor Pool, a lot has been happening. We have two civilian automobiles in progress, one big scale and one small. On the small one, the Zebrano Model A Ford, we finally got the main body assembled and fastened to the chassis:

You can see all the dust that blew in from the Hangar after all the work on the Be-4

Later all the rest of the fenders, headlights, and radiator, as well as the wheels were added:

That's as far as we got on that one. On the larger one, the Monogram 1/24 scale Packard, a lot got done. The main fenders got their coat of gloss brown:

Since the fenders were being painted the dark brown, we also masked off the main body and shot the same brown trim on it:

A bit of a test fit later, we see how well this is gonna look....provided I don't screw it up first. You can also see that the seats had been painted leather.

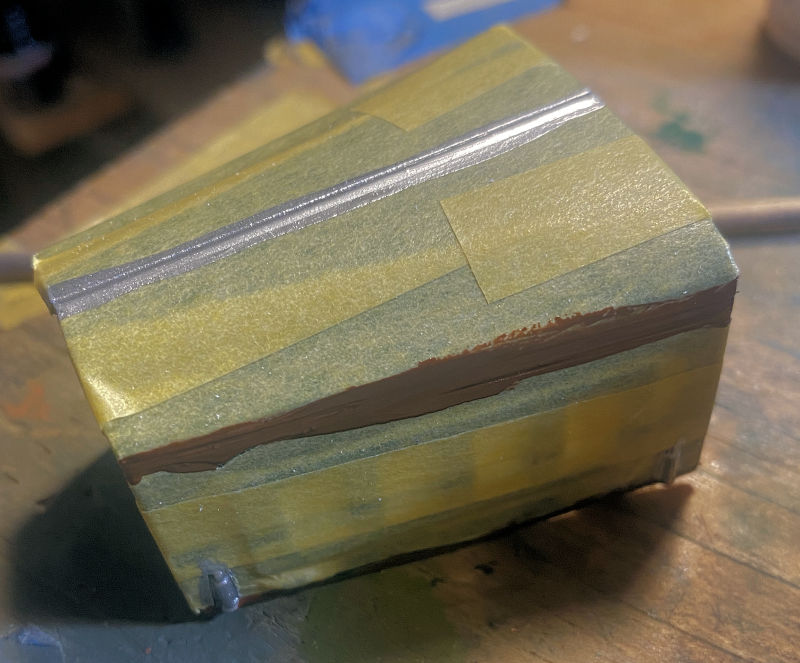

The main hood over the engine had been giving us problems with the green base coat, but it finally went down smooth and the gloss coat as well. This was then masked off for the brown trim to be painted as well as some chrome bits molded in place:

Final result, better than expected:

You can see we started painting the chassis as well. More to come on this later.

There's a third civilian vehicle we're working on the ACE 1/72 scale Ford 1937 stakebed truck. First assembly was the chassis:

We then got half the cab finished:

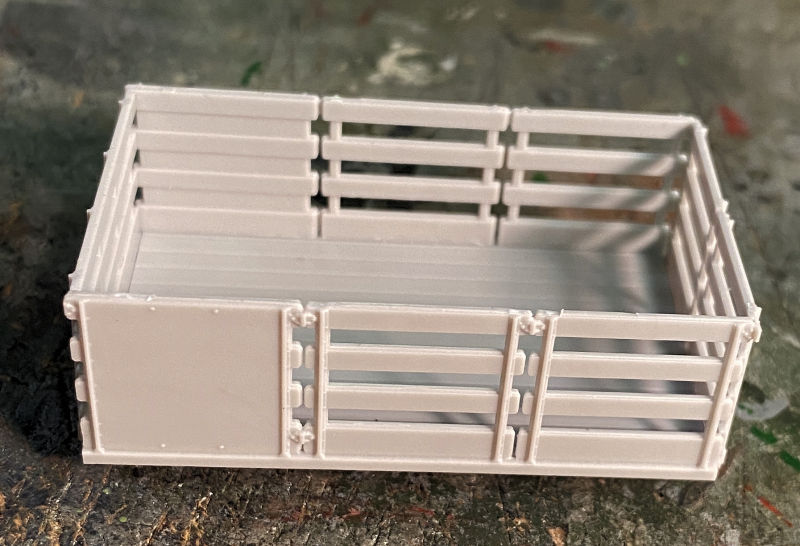

Finally, the stakebed:

Great detail on this ACE kit. Here it is all mocked up:

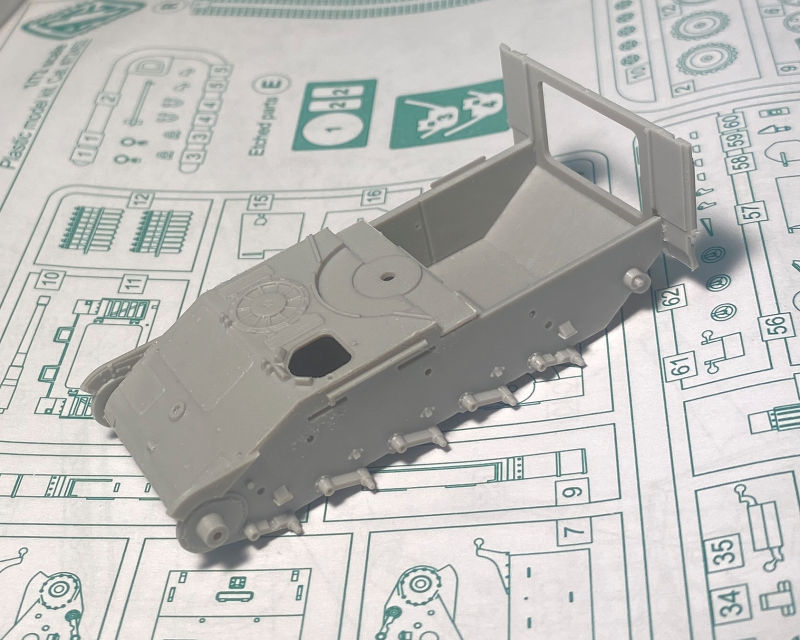

These next few vehicles are ones we started since I've been wanting them in the collection or awhile. First is this French AMX Mk.61 self propelled gun. Basic lower hull was assembled first:

Another French AMX vehicle, this time the AMX-13 DCA. Again, lower hull assembled first:

We got a little further on the South African Eland 90, even building the basic turret:

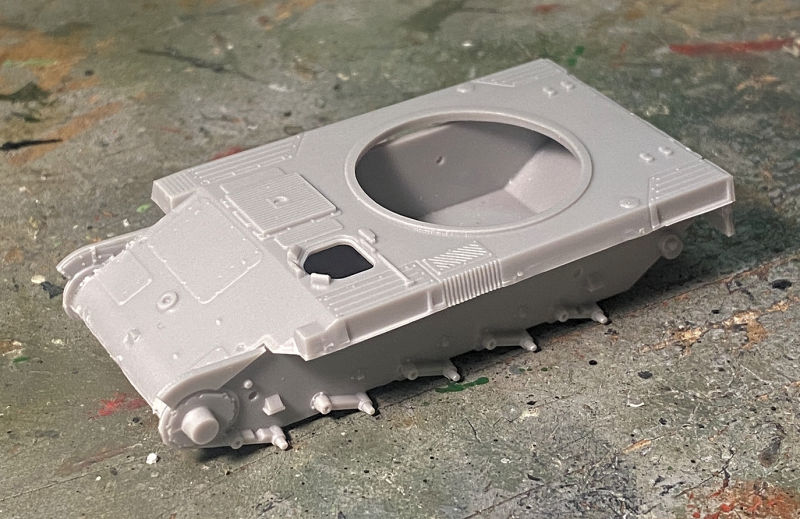

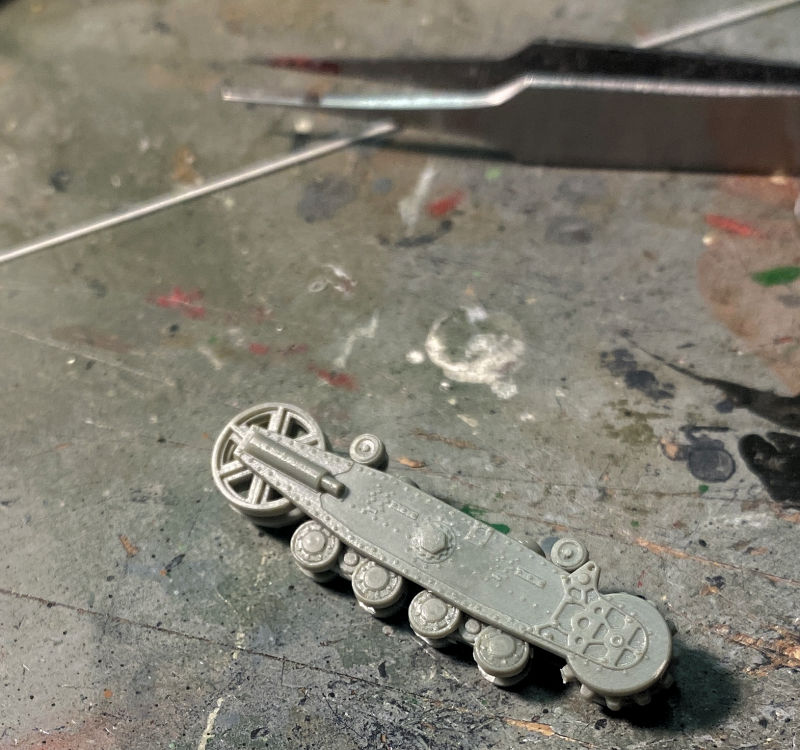

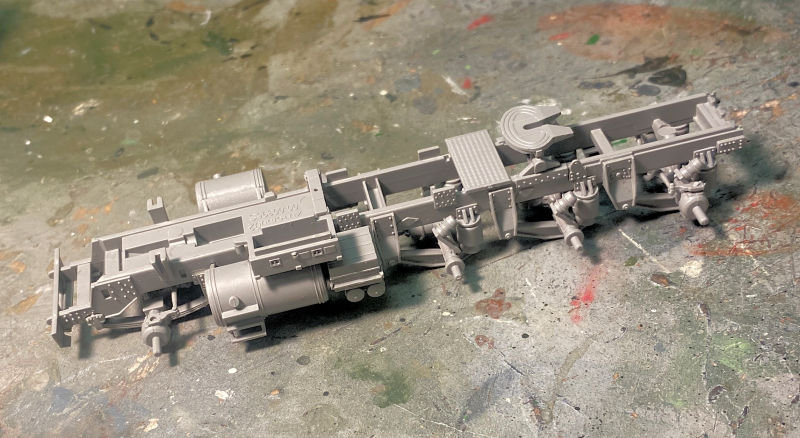

Finally there's the Russian Br-5 280mm mortar from ACE. This one took a bit of time since the main tracked running gear had so many parts to assemble. First were all the road wheels on the main part:

Then the two outer casings went on, trapping the (twin) idler wheels, drive sprocket and roadwheel assembly inside:

Had to do this twice:

And we still have to add the link and length tracks! Moving on, we assembled the main carriage:

Finally we got to the gun:

The trunnion will be a tough build so we left it at that....

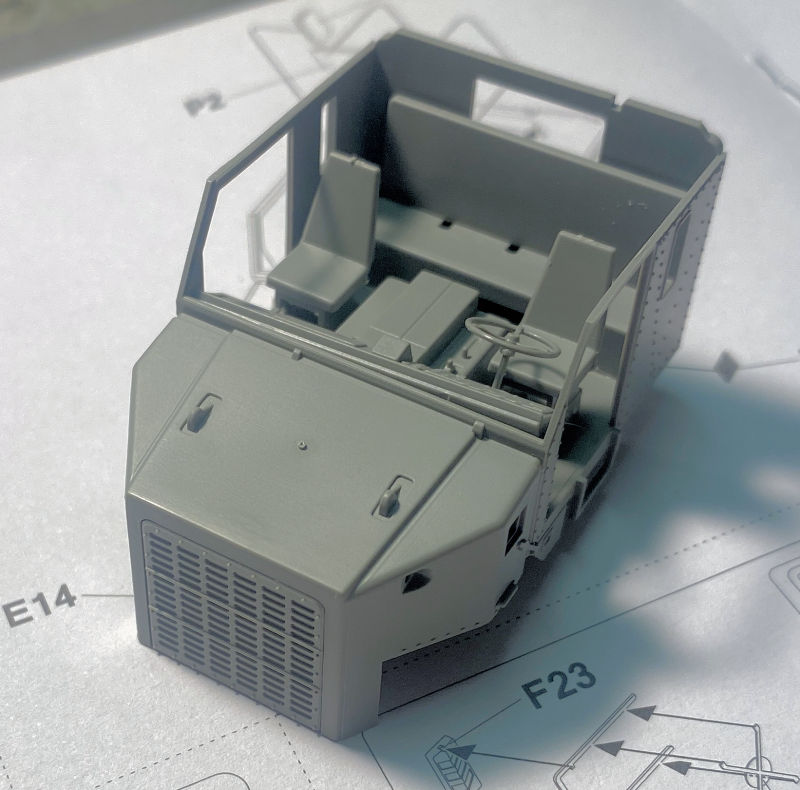

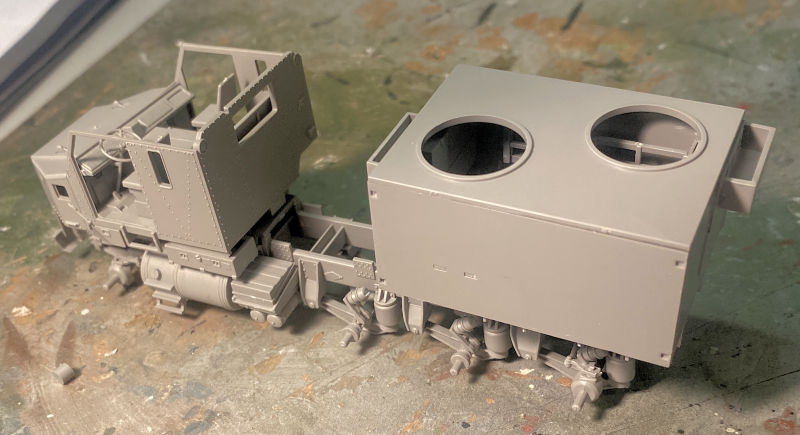

Our last project to look into is the M1070 gun truck. We took some time to get the main chassis almost fully assembled:

The cab was started next, leaving room for painting the interior before it is closed up:

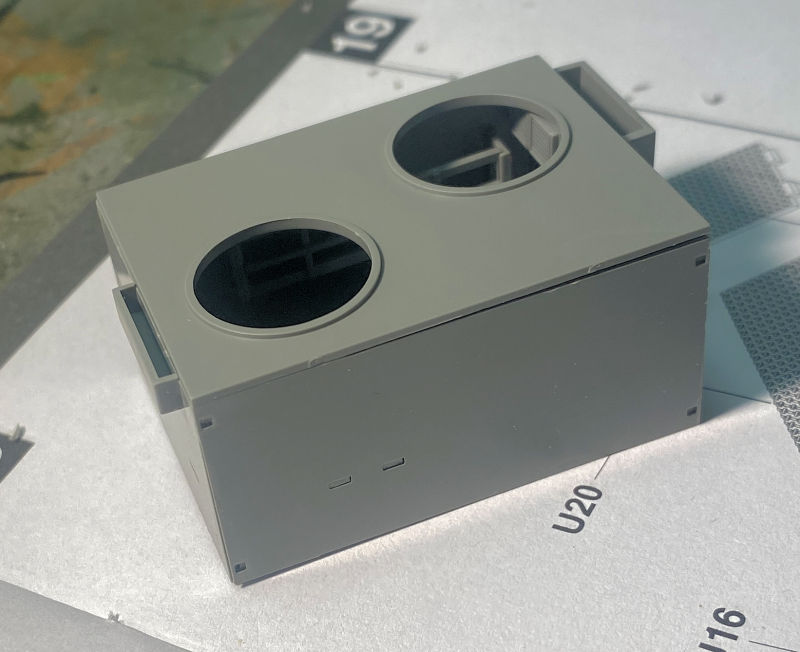

Finally the gun bed was built up, sans barriers. There's lots of interior detail that can barely be seen:

There's still a center section to build up, but these three components are pretty much done overall:

One last treat before we conclude this tour, Rocket the Raccoon has been mostly painted up. I still need to do his nose, eyes, teeth, gun and his outfit:

That concludes this latest tour of Maddog Manufacturing, I hope you enjoyed it. As always, comments are welcome.