Welcome to the next tour of Maddog Manufacturing. It's gonna be a pretty long one, but most of the work to be seen will be in the Motor Pool. Very little was done in the Hangar and Shipyards. So, all aboard the trams, and remember to keep hands and feet inside at all times.

That being said, let's check out the progress in the Hangar....

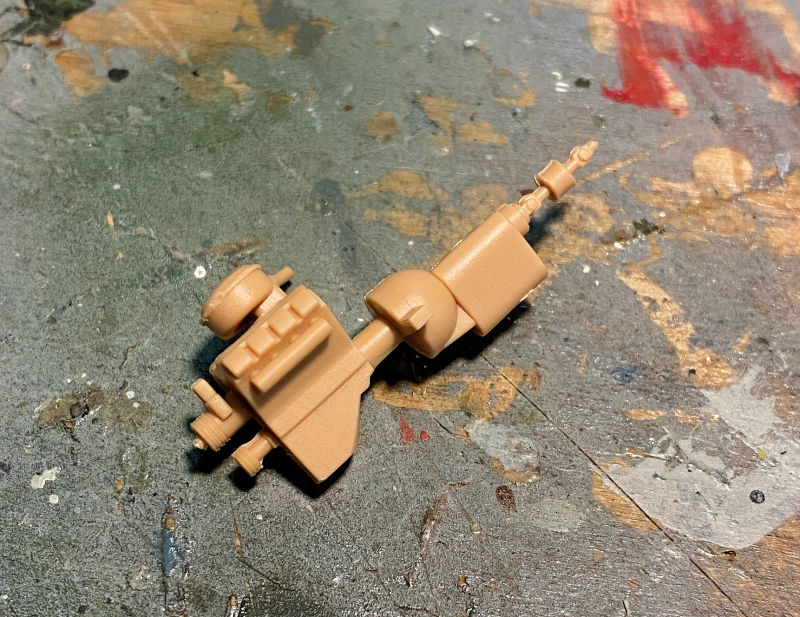

One of my shelf queens I've been trying to move forward on is the C-54 that I started quite a few years ago. This has been a far more complicated model than expected. This week, all we did was to complete the last of the four engines that still needed to be built. Each one had seven parts to it:

Those will be painted sometime later then we'll be able to move on.

Over in the Shipyards, a little more progress was done, almost all on the British Vospers 73ft MTB.

First, after the black bottom dried, it was masked off so that the light grey could be shot on the hull:

Here it is after the Grey was shot:

And now the masking has come off:

Later this will be gloss coated and decals added, then the clear parts will go in the portholes and we'll move on.

The last thing that was done in the Shipyards was painting the green on the deck of the Vospers Perkasa:

That's all we have for this week in the shipyards, it's time to go check out the Motor Pool...

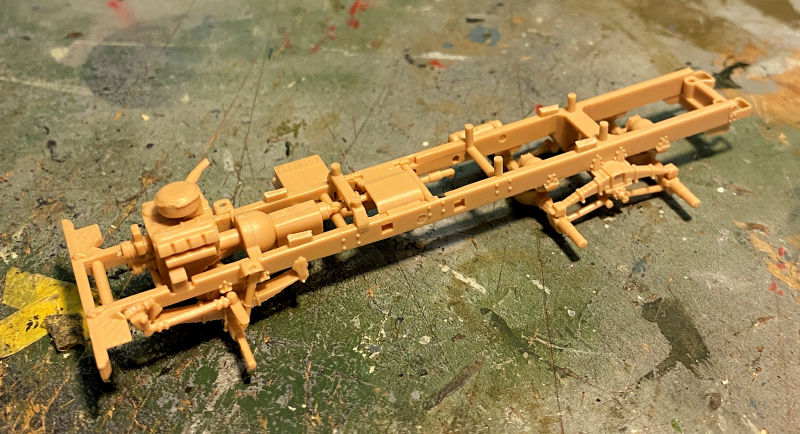

There's a lot that's been happening in the Motor Pool this past few weeks. First up is this Russian truck that I chose because it as simple and easy to build. This is the Hobby Boss Russian Ural 4320 cargo truck, and the first thing that was done was to assemble the rather basic engine:

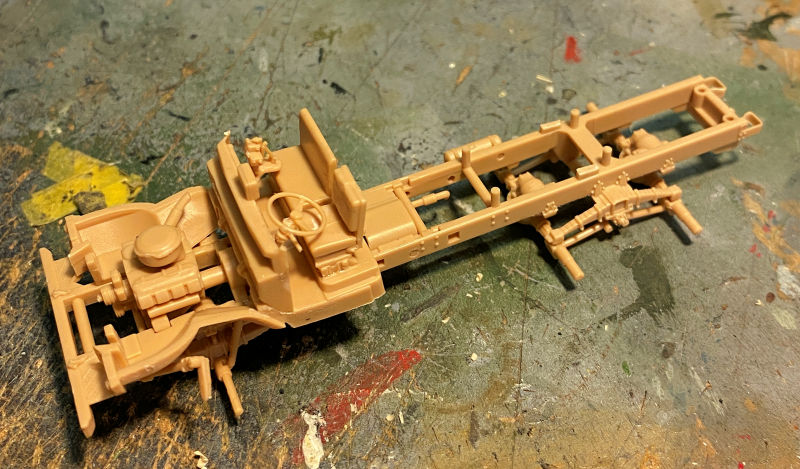

It won't be seen so that is the extent of that work. Once dry, it was added to the chassis along with all the other suspension parts:

Later we added the spare tire cradle that sits behind the cab:

The cab itself just needed fenders attached:

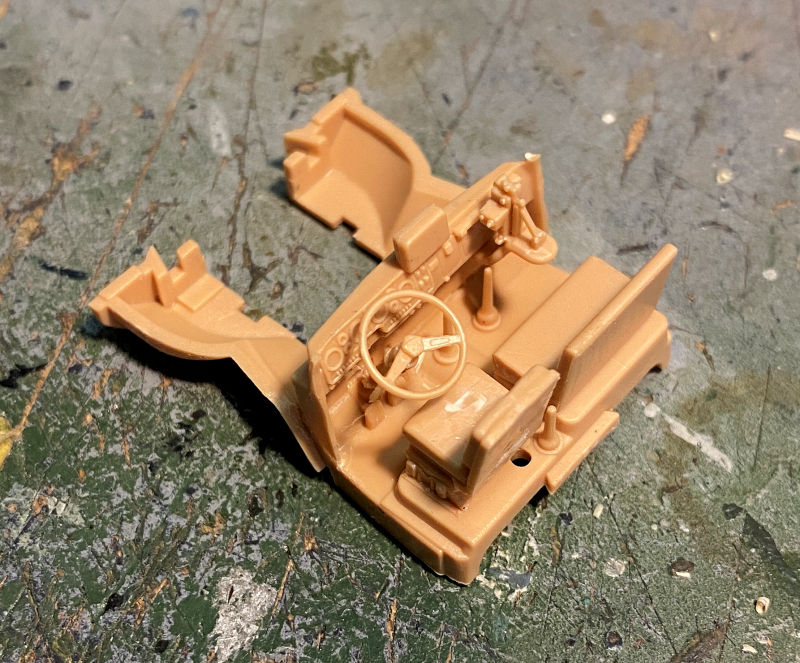

The interior was done next, there's a lot of detail inside:

Here is a dry fit to see how it fits on the chassis. Because of the unique way it goes around the engine, this was a tough fit. It looks great in the end though:

Finally, painting was begun. Inside of the cab was painted first, and then I found a decal for the dashboard. Cool! That went in next:

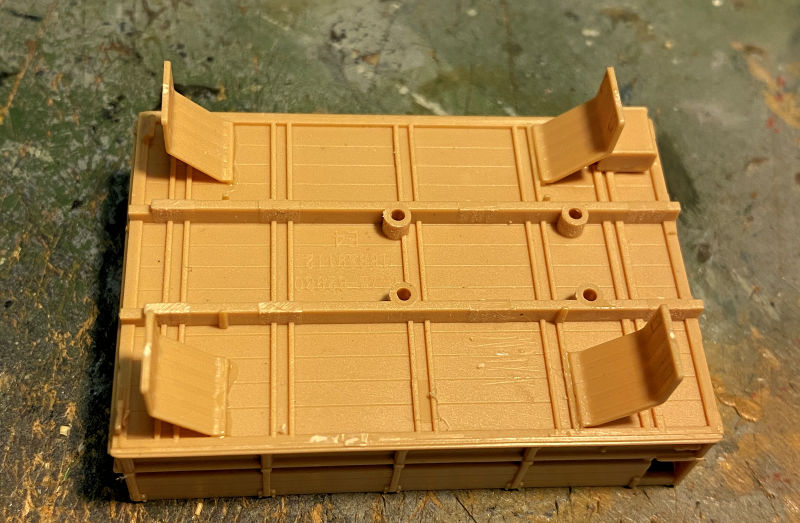

We then assembled the bed of the truck while the decal was drying:

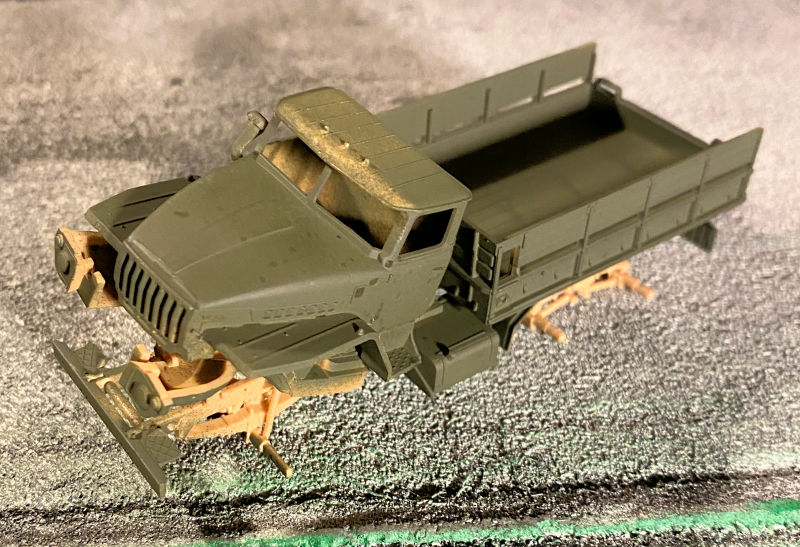

After that, the exterior was painted. Here is everything roughly dry fit together:

Hopefully a gloss and decals will go on soon.

Moving on to the next bay, we have another truck, this one pulls the trailer holding the SA-2 reloads. Paint was added to the interior, but there's still more to do. I have the driver to paint. Meanwhile additional parts were added to the bed and the cab was dry fit to the front of the truck:

The trailer then received all the remaining detail parts to be ready for paint:

Next we just had to assemble the load, one SA-2 SAM:

That missile has 20 parts to it. Not like the Hobby Boss one that I built before!

Moving on, we dry fit everything together. Looking good:

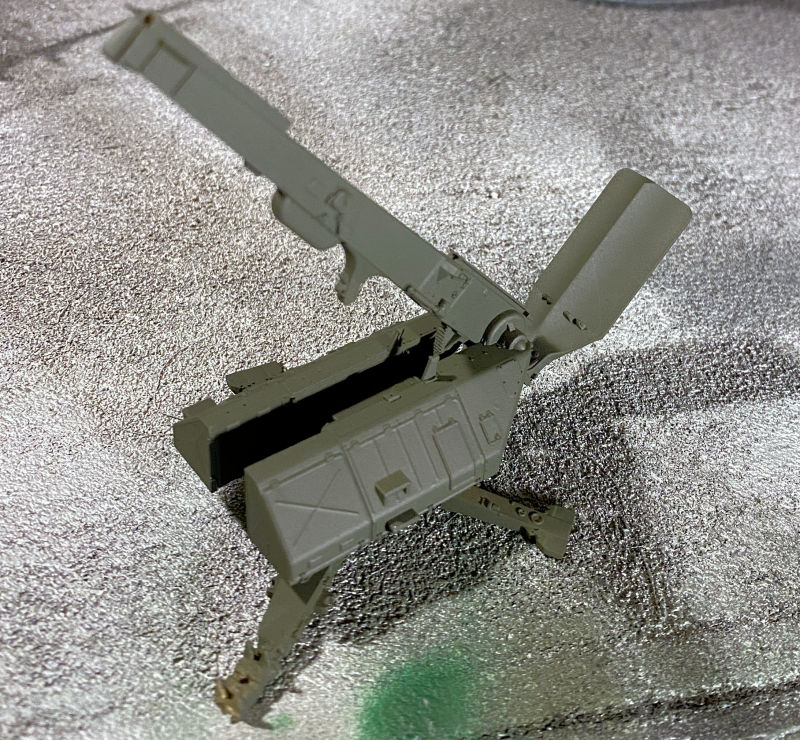

After that, the launcher had to be built:

Finally, the paint came out again. The whole exterior got shot with the green basecoat:

Don't worry, the launcher base did not break, it comes apart so I left it that way until later.

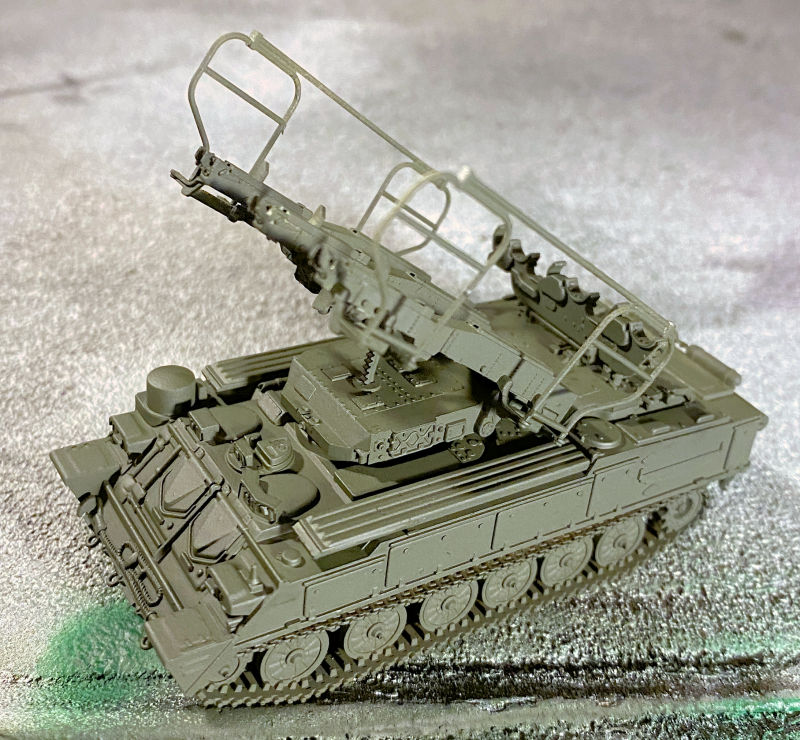

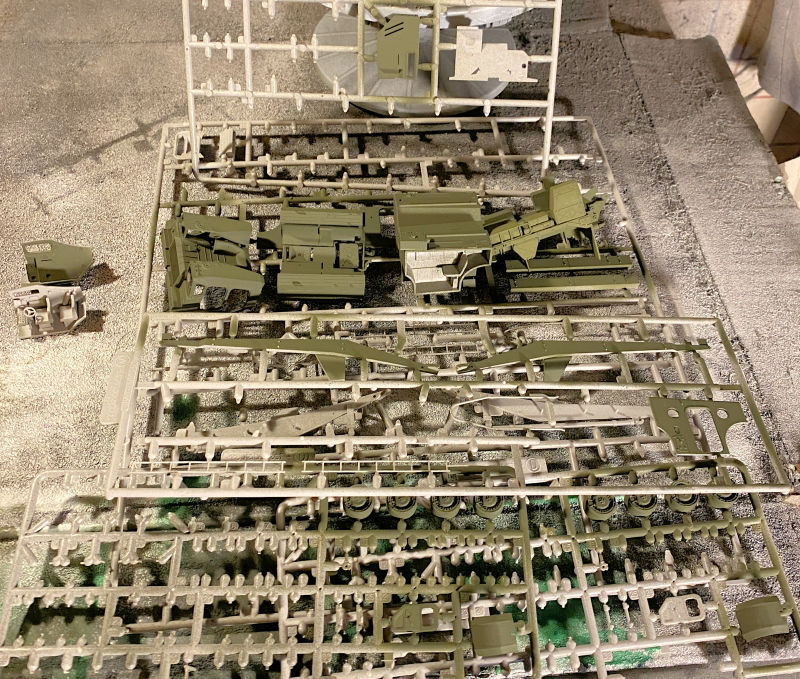

Since the green paint was out, the next one to get a basecoat of green was the SA-6 Gainful in the next bay:

That is coming along well. We also went to the next two bays where we painted most of the parts for the two SCUD trucks. First the SCUD C:

And then the SCUD D:

Finally, we shot the green basecoat over the SA-2 launcher; the Hobby Boss one. I call it Launcher No. 5 since it's the fifth one I'm building for my SA-2 SAM site:

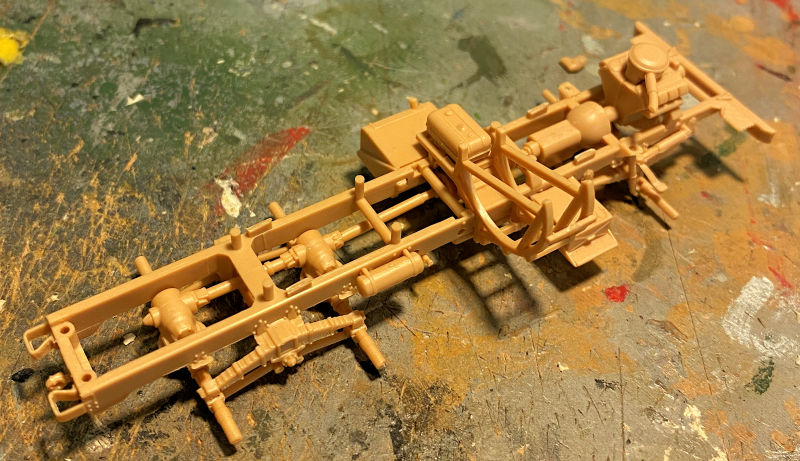

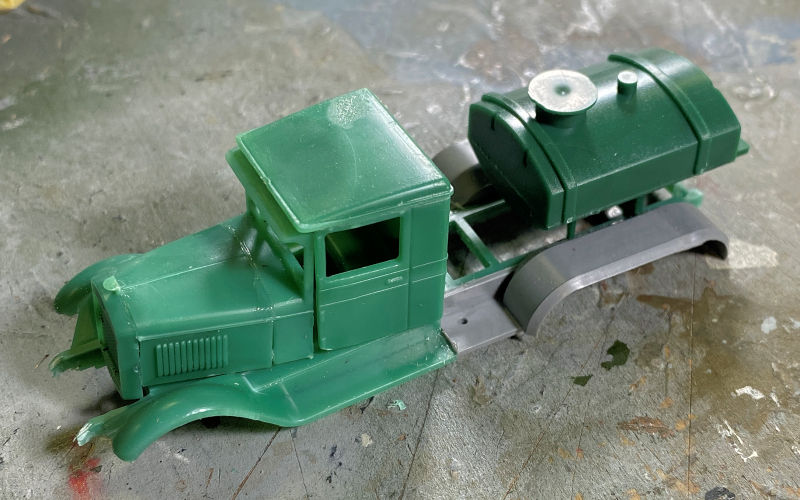

After all that, it was time to get back to building something. We started on this old PST Russian PMZ-2 fire tanker still sealed in the shrink wrap. Out it came and the basic chassis was built:

The the cab parts and the tank were built. Here they are dry fit on the chassis:

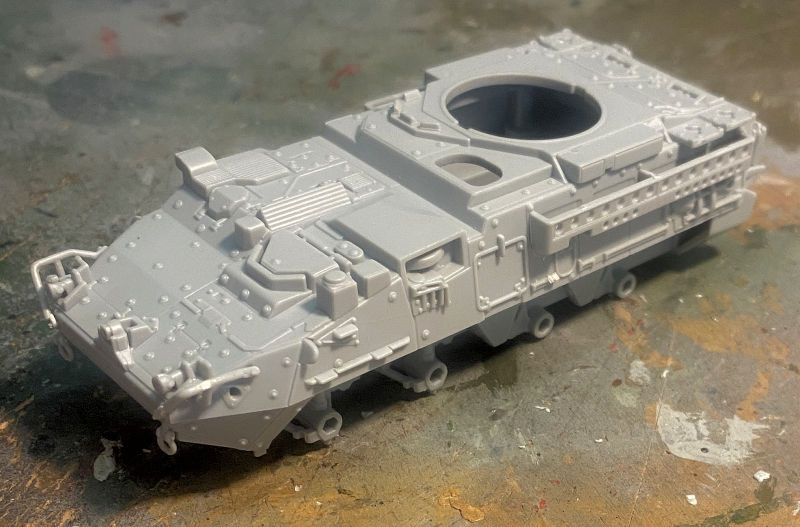

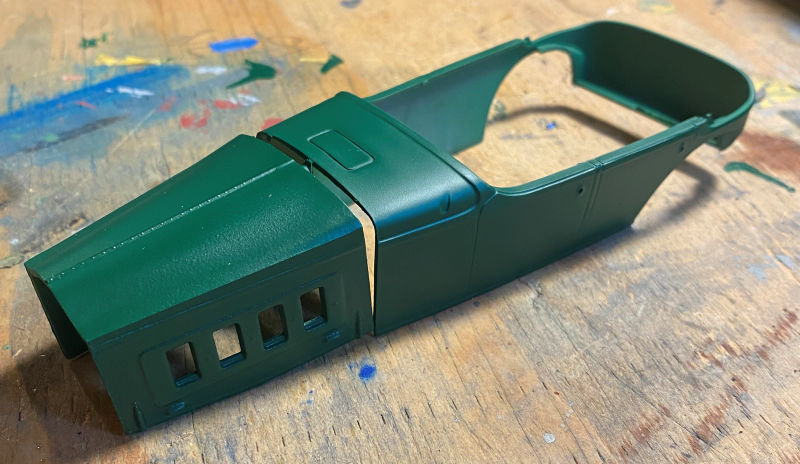

That's where we stopped on that. After that I was looking for something quick and easy and so the dragon Stryker Dragoon came out. I was always trying to get this to add to my Stryker family, and finally it had come in. The Hull was built first; it took all of 15 minutes:

Next the turret was built. Another five minutes, but we were taking our time:

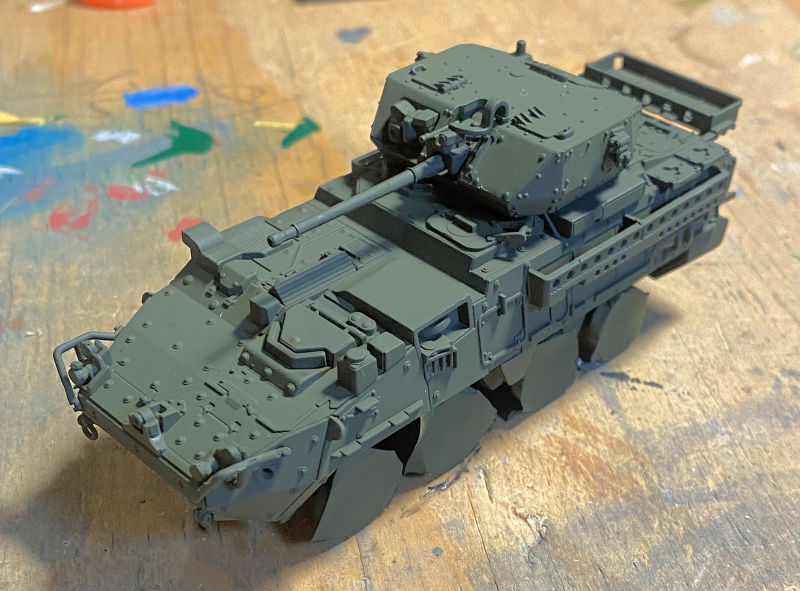

Next the inner wheel hubs were added. Dragon makes them so they all roll, and they roll well! The outer wheels will go over these, after the tires are glued onto them. Additional parts were added to the hull as well and the turret was placed:

The inner wheels were masked and the whole thing got it's basecoat of green:

Wow, that was fast!

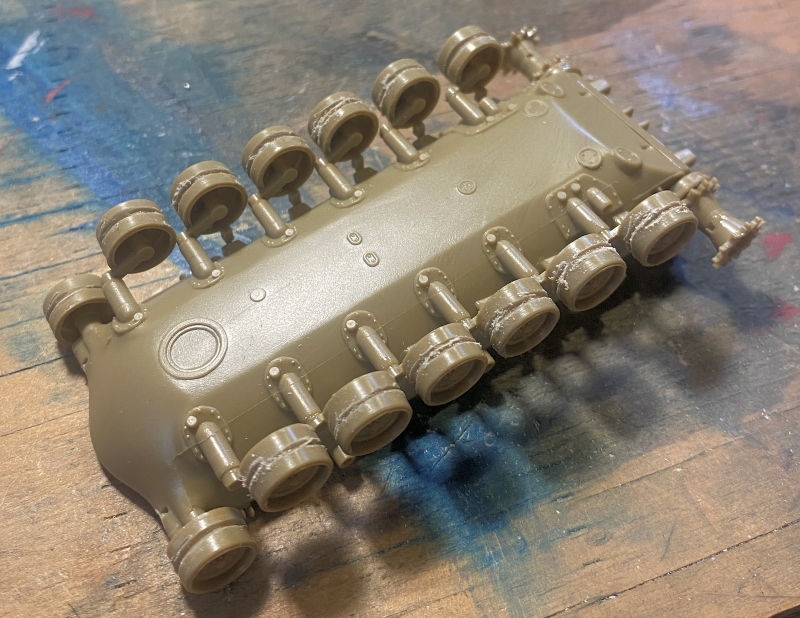

Following these, we pulled out an ancient ESCI M48A5, the only Patton variant issued in 1/72 scale that I didn't have in my collection. First, the wheels were grooved to give the appearance that it's two roadwheels per axle and not one big fat slick each. Then they were all installed on the lower hull:

Next most of the detail parts went on the upper hull:

And then the turret was built, just a basic assembly at first:

We added the tracks and then dry-fit everything together to see how all of it fits. Looking good:

Just before painting, the last detail parts were added and the searchlight was built and installed. While trying to get the hand rails on the side of the turret to stay where they are supposed to, some of the holes we drilled ghrew too big. We made an effort using acrylic putty to fill them in. We were mostly successful:

The dark green basecoat was applied next. Later we'll break out the Silly Putty and start adding the other three camouflage colors:

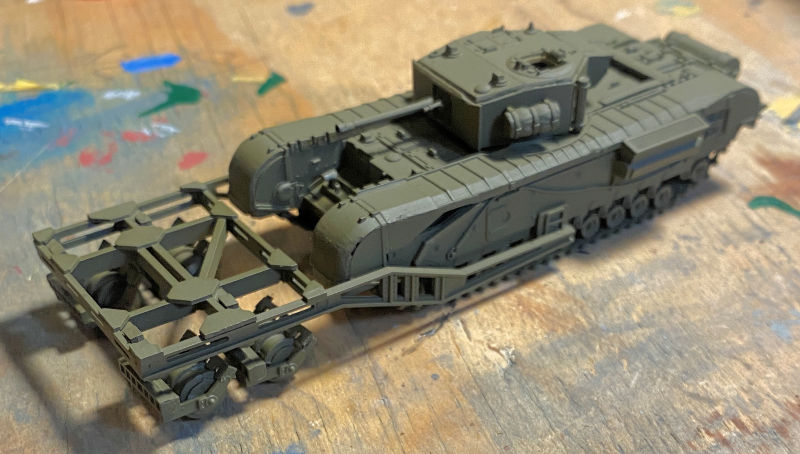

While contemplating another project while the Patton dried; I spied another ancient ESCI kit: a Churchill with mine rollers. I'd already built one, but this gave me options for a Canadian one, so we got started on that for my Canadian Army. First we built the mine roller frame:

Next we started on the basic hull getting most of it assembled:

This is gonna be a long beastie again:

Later the turret was built, and placed on the hull, again with the frame positioned in front:

Finally, the tracks were completed and the fenders installed, along with most of the additional detail parts. I had trouble with those fenders as they were pretty warped:

Yes, I left the turret hatches off; there's a TC that goes there and I wanted to have them left open for him to pop his head out.

Finally, all the mine rollers were completed and installed on the frame. Once dry, the whole assembly was glued onto the tank:

After that dried, it got a basecoat of Olive Drab:

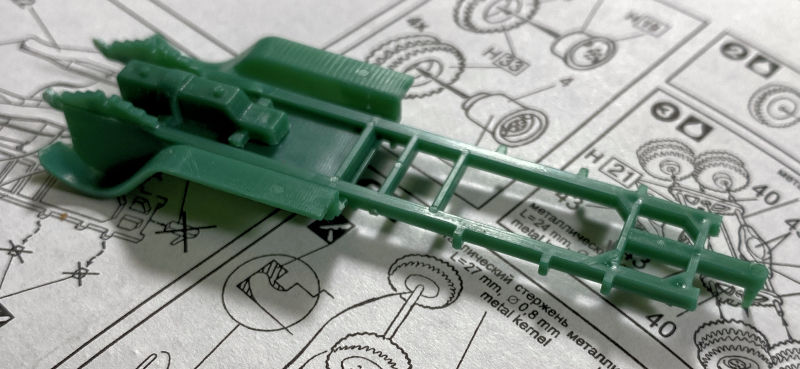

Finally, I tried again to get the T-17 rocket mounts to work. The instructions show one end of the barrel mount attaches under the T-17 rack and is not supposed to be glued so the whole thing moves when the gun is elevated and lowered. However, There is no hole or pin to go there to hold it; the "ring" on the bottom of the rack is molded solid and the rocker arms also have closed up ends where this is supposed to be pinned to move. So, after five efforts later to get these things opened and fastened correctly in a way that allows movement, I finally ended up here. The white strip on the side of that rocker arm is to hold the larger loop in place; it kept breaking off. After gluing it back five times, I decided to reinforce it with that. The other one got one too later. The Exacto blade shows how small these things are:

These are all the parts for the rocket rack's mount along with the rack itself. If you look closely, you'll see my attempts to get the upper rocker arms done right to make this work. The side mounts went together well at least. This was taken before the reinforcement attempts, but you can see the outrageous parts I have to deal with. It's no wonder I never never finish a UM Sherman:

Back when we shot the green on the Perkasa deck, we had also shot the same green on my Packard. The first time it had some dust on it, so we sanded it down with very fine grit:

Later a second coat was airbrushed on. Yes, it looks a bit grainy, but it is a dull color. I'm going to buff it and then gloss it:

And that concludes our latest tour tour of the plant. I hope you enjoyed it, feel free to leave comments, they are always welcome.

Thank you for coming in!