Post by darcy on Nov 20, 2011 13:17:28 GMT -6

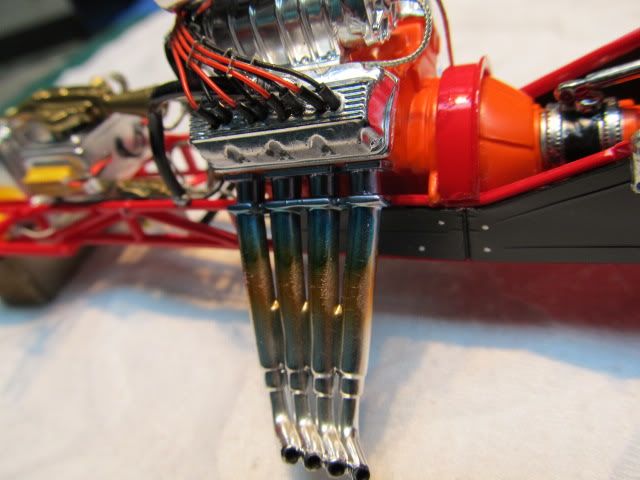

The first thing you need to do is Strip the Kit chrome off the headers by soaking them in EASY OFF oven cleaner. Until the parts are clean the chrome comes off right away but the clear base takes longer up to over night.Once your parts are clean they need to be washed with dishsoap and rinsed.The headers now need to be sanded as smooth as posible and sand off any clear base that mite have been left behind.It's very important that everything is nice and smooth scratches and flaws will show up in the finished product if not fixed now.

The parts to be Chromed now need to be primered. I use AlcladII black primer which fills in fine scratches and provides a good base for the AlcladII GLOSS BLACK BASE that must be applied before any shiny AlcladII colors CHROME, POLISHED ALUMINUM,STAINLESS STEEL, ect are used.I dry painted parts in a food dehydrator and always wait 24 hours between coats.

After the primer is dried you must apply two light coats of AlcladII GLOSS BLACK BASE It is important to let the black base dry well because it takes a while to harden up and if you get finger prints in it they will show threw to the Chrome later.

After the black base dries well, you have to ad 2 light coats of Alclad II Chrome.4 really light coats would be better than one heavy coat.You keep adding light coats until the desired sheen is achieved.If you apply to much paint at once it will come out dull in the end

Once the Chrome has dried you need to ad Layers of Alclad II Hot metal paints.The 1st layer is tranparent PURPLE closest to the flange side of the headers,next a strip of transparent BLUE followed by a strip of transparent Yellow.You just slightly overlap these colors.All of the above mentioned paints were sprayed threw an air brush at 12psi,Alclad II paint does not have to be reduced it comes ready to spray.One small bottle of Chrome goes along way

I hope this is of some help thanks for lookin!

Darcy

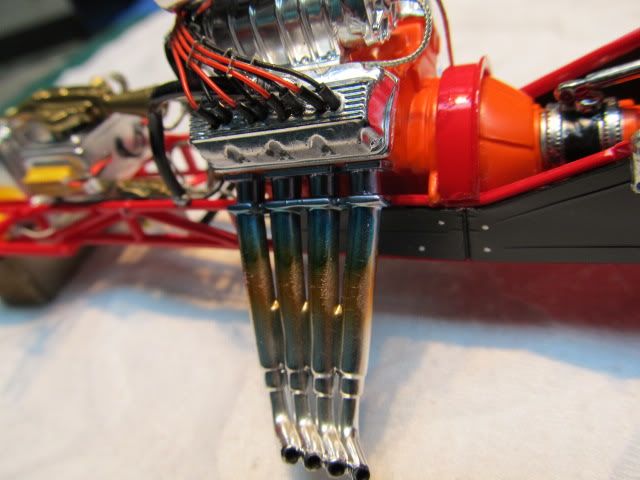

The parts to be Chromed now need to be primered. I use AlcladII black primer which fills in fine scratches and provides a good base for the AlcladII GLOSS BLACK BASE that must be applied before any shiny AlcladII colors CHROME, POLISHED ALUMINUM,STAINLESS STEEL, ect are used.I dry painted parts in a food dehydrator and always wait 24 hours between coats.

After the primer is dried you must apply two light coats of AlcladII GLOSS BLACK BASE It is important to let the black base dry well because it takes a while to harden up and if you get finger prints in it they will show threw to the Chrome later.

After the black base dries well, you have to ad 2 light coats of Alclad II Chrome.4 really light coats would be better than one heavy coat.You keep adding light coats until the desired sheen is achieved.If you apply to much paint at once it will come out dull in the end

Once the Chrome has dried you need to ad Layers of Alclad II Hot metal paints.The 1st layer is tranparent PURPLE closest to the flange side of the headers,next a strip of transparent BLUE followed by a strip of transparent Yellow.You just slightly overlap these colors.All of the above mentioned paints were sprayed threw an air brush at 12psi,Alclad II paint does not have to be reduced it comes ready to spray.One small bottle of Chrome goes along way

I hope this is of some help thanks for lookin!

Darcy