|

|

Post by Steve Ski on Apr 12, 2018 20:50:40 GMT -6

This will be an SBS on how to deal with nylon 3D printed parts and kits. This kit was not cheap by any stretch of the imagination, nor was it easy to work with. The figures are not included in this SBS, but are only there for scale reference.

There's a lot of prep work that is required before you ever touch a paint brush. So, strap in as we go inverted and slam the throttle to the fire wall, Yehaaaaaaaaa!

Getting Started

Talk about a big undertaking, this is it! Ya know, I heard it said many, many moons ago, " When yur hind quarters and elbow in alligators ya begin to wonder why ya came to drain the swamp." HA!

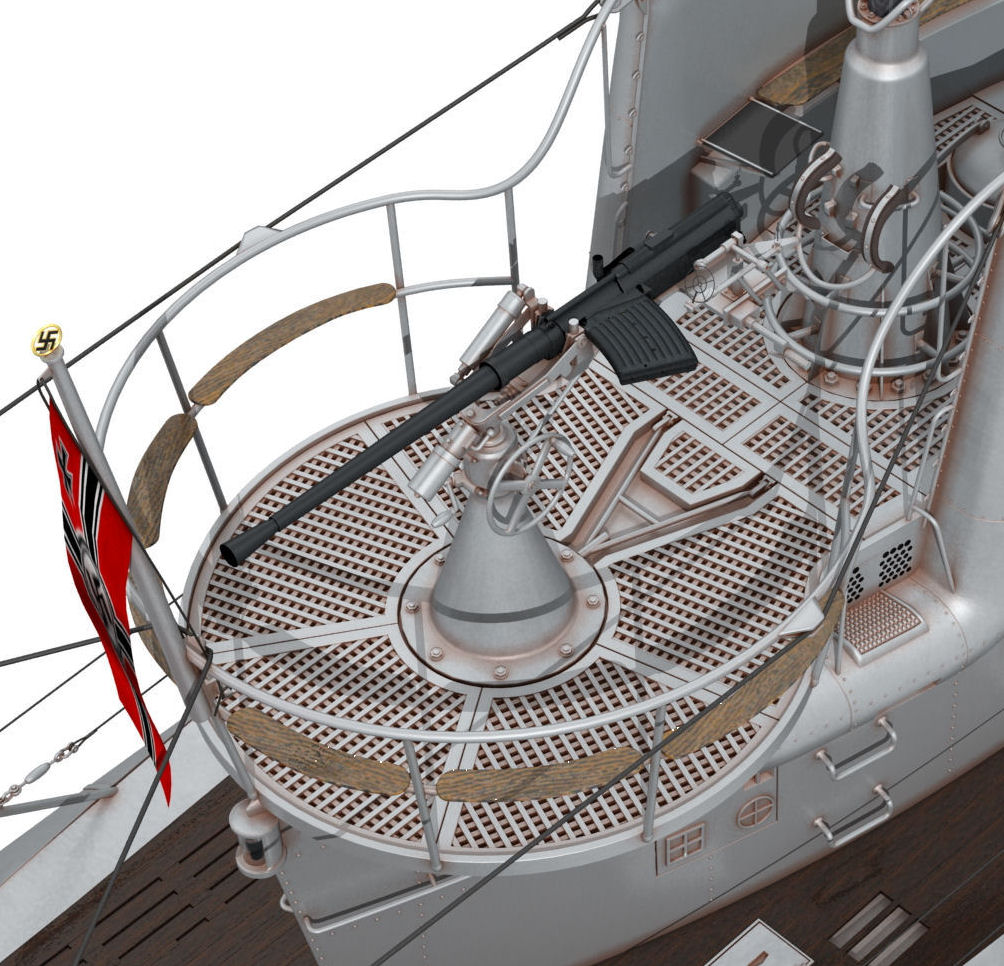

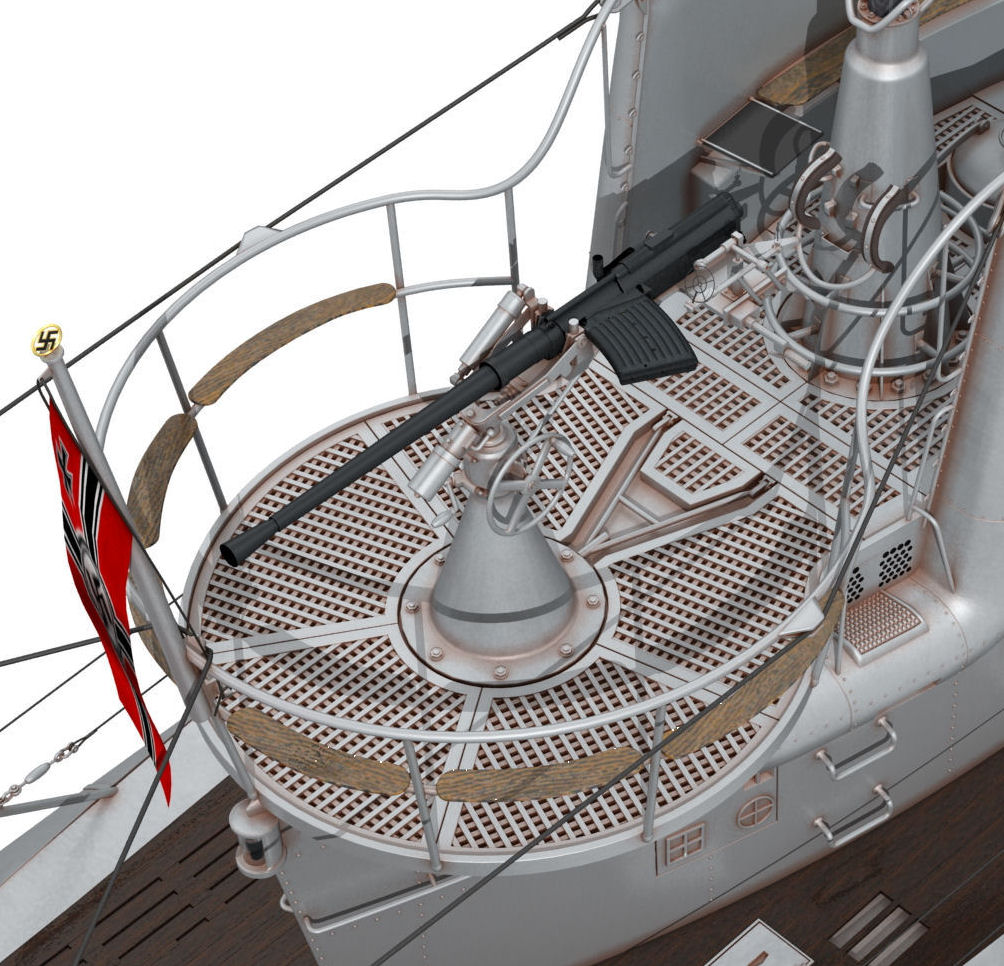

When this beauty arrived I realized this was not gonna be much fun getting it prepped for paint. This gun deck is a 3D print, 1/16th scale rendition, accurate and impressive from Shapeways, specifically designed by Sasa Drobac. Link is here: www.shapeways.com/shops/distefano_3dprint

Sasa has a pretty impressive line up for boat builders of all kinds and many scales, so this is a good source. However, back to my initial impression upon delivery, yikes! If you've never dealt with nylon printed 3D parts you're in for a surprise. It's a lot of work and I never did the intel search to find out otherwise, it never crossed my mind. My boof!

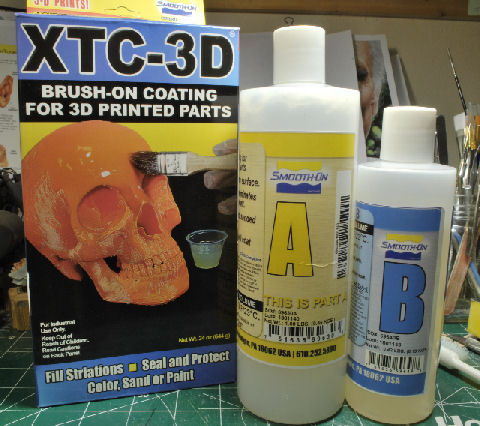

Prepping The Pieces For Sanding

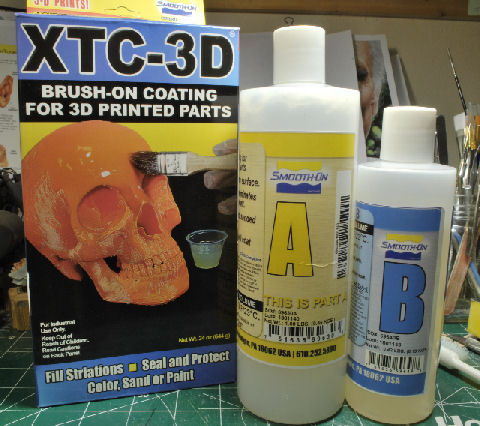

Not all is lost, won't get done lookin at it anyway, right? The nylon print actually is better for anything that is large or has delicate configurations. But, it does have a fuzzy, or grainy appearance and does not like to be sanded unless you give it a resin coat or hit it several times with a primer. After much research I went with the XTC-3D resin filler, worked like a charm. However, as with any resin, make sure your mixes are exact or they won't dry and that tacky coat is a real bugger to get rid of. Trust me on this, I ran the learning curve for you, lol.

Once the resin had cured and was sanded with 200 grid paper the deck began to look much better. All kidding aside, this is a lot of work, so be prepared to spend days getting it to where you can paint it. In the end, it's all worth the grumbling because nobody makes anything coming close to what I needed and Sasa with Shapways was the only answer. Sasa will special design to your needs, which is what he did here. It took a bit of communication back and forth to get it right, but like I said, well worth the extra time to get what you are looking for.

More to follow, so any questions or comments, holler. Cheers, Ski.

|

|

|

|

Post by BUCKY on Apr 12, 2018 22:05:32 GMT -6

Looks like quite a project! I'm all in for this!!

|

|

|

|

Post by JEFF on Apr 13, 2018 2:05:32 GMT -6

This is cool, to say the least. I'm in.

|

|

|

|

Post by JCON on Apr 13, 2018 8:22:11 GMT -6

Wow something new from the Ski Bro Master!!! Nice!!! Have not seen anyone really tackle a printed kit so this will be very good to watch thank you!!!

|

|

|

|

Post by Steve Ski on Apr 13, 2018 8:44:36 GMT -6

Thx Bucky, Jeff and Joe.

I've been wrestling with this set up for over three weeks now, so I'm hind qtr and elbows deep into it, HA!

Sad thing is, the outside work is fast approaching, as you can attest to Joe. One good thing, I'll be making the club meetings starting the end of next June, 2019, that is. Yehaaaa!

Cheers, Ski.

|

|

|

|

Post by ARMORGUY on Apr 13, 2018 8:57:12 GMT -6

Another Ski-project, isn't that good news to start the weekend with ?! I'm in my good man !

|

|

|

|

Post by dogfish7 (R.I.P.) on Apr 13, 2018 9:32:14 GMT -6

Added to my Bookmarks.

|

|

SteveM

SETTLING IN

Posts: 411

Likes: 967

|

Post by SteveM on Apr 14, 2018 1:02:16 GMT -6

Great tip on the resin fillies for the 3D parts. Looks like an interesting project too  |

|

|

|

Post by Steve Ski on Apr 14, 2018 19:56:47 GMT -6

Thx AG, velcomen aboard. sorry, my German is a bit rusty, lol.

Thx Bruce, more to follow.

Stevo, thx buddy!

|

|

|

|

Post by Steve Ski on Apr 14, 2018 20:02:39 GMT -6

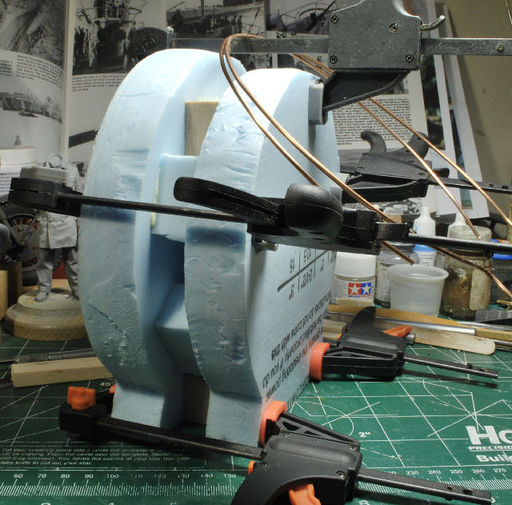

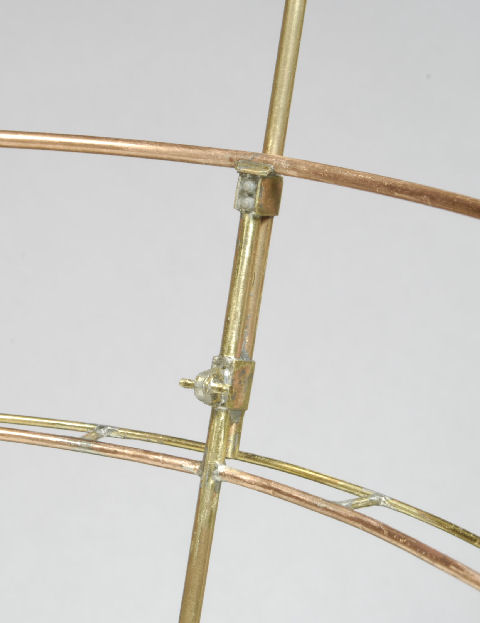

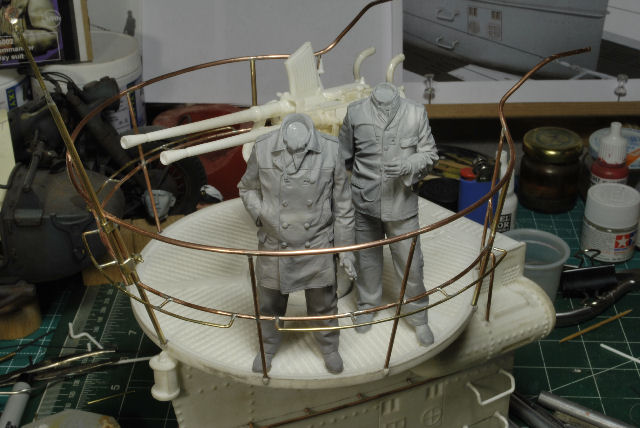

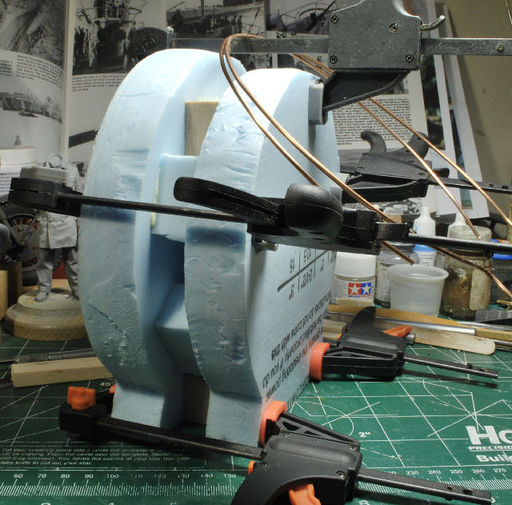

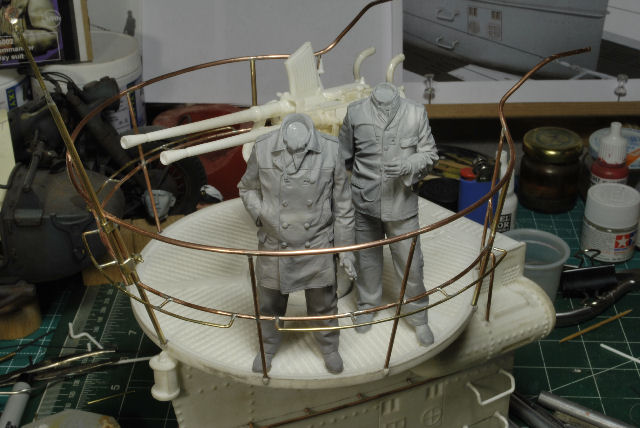

Building the Railing

Making the railing was pretty much a piece of cake, except trying to figure out how to keep all rails in line and correctly placed. I made a jig out of blue construction foam as a template in the desired dimensions for this scale. No, it ain't exact, but it'll do, close enough, lol.

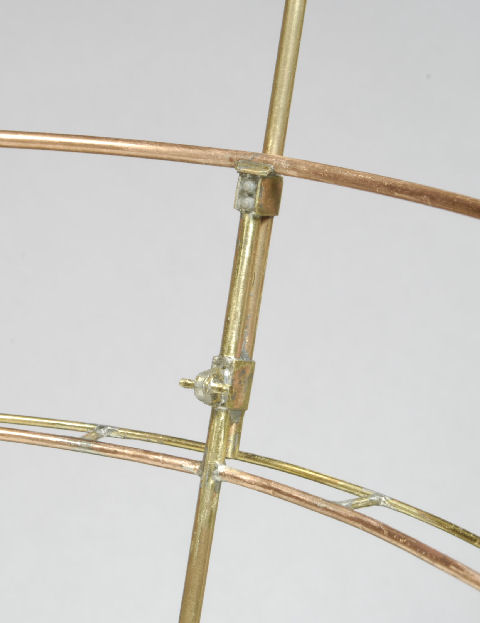

I used standard 12/3 Romex copper wire for the top rail, 1/16" copper tubing for the mid rail and 3/32nds brass tubing for the main rail posts. Once the pieces were in place I soldered the mains. The mid rails were cut using the copper tubing and then attached using steel pins through the verticals to keep them in place.

Caution: Remember to use "lead free" solder only. I'm not sure if you can still get the old stuff, but I found some in my stash. The fumes are not good to deal with. Wez gots way too many kits to build to be using the old stuff anyway, right?

See ya soon with another update and thx for watchin. Cheers, Ski.

|

|

|

|

Post by BUCKY on Apr 14, 2018 20:18:49 GMT -6

A fine way to build a railing!!

|

|

|

|

Post by JCON on Apr 14, 2018 20:20:34 GMT -6

Nice job bro... ruck on...

|

|

|

|

Post by Steve Ski on Apr 15, 2018 8:33:30 GMT -6

Thx Gents. See, even a blind squirrel can find an acorn of an idea evr now and then.

Ah, the diversity of blue construction foam, handy stuff. It ain't just for basements any more, HA!

|

|

|

|

Post by ARMORGUY on Apr 15, 2018 8:48:35 GMT -6

You da sub man Skibro !

|

|

|

|

Post by JEFF on Apr 16, 2018 2:18:28 GMT -6

That looks awesome, Steve. Great idea with the foam.  |

|

|

|

Post by ARMORGUY on Apr 16, 2018 8:34:13 GMT -6

This is pure foamism !

|

|

|

|

Post by Steve Ski on Apr 17, 2018 10:47:20 GMT -6

Lol, foamin at the mouth whilst doin it too, HA!

Thx Brotha!

Thx Jeff, seemed like the thing to do.

Cheers, Ski.

|

|

|

|

Post by Steve Ski on Apr 17, 2018 11:19:59 GMT -6

More Soldering On Deck

The seat supports were next in line for soldering. I used some smaller diameter copper tubing for the supports and soldered them in the appropriate locations along the mid railing. Clamping the pieces in place was a bit of a challenge, but once I got a system going it went quick.

This portion of the build should have been posted last time, sorry

____________________________________________________________________________________________________________________

Flag Pole And The Kriegsmarine Flag

Now, dealing with these tiny scratch built parts for the flag pole was a real "Baby Rump Kisser'! Pretty much every time I started to solder a piece anywhere close to something that had already been done the parts moved from the heat, Yikes! So, I had to work fast and I actually used the plumbers technique of brazing rather than having the solder already on my tip. I never claimed to be an expert at this, just tellin yall how it went, lol.

Note: Use caution when filing the slag away from your work, if you go too thin you'll be soldering again, thin joints won't hold under pressure or torque.

Once again, the rhythm was kickin and I got er done. The rope loop was a real hoot to get lined up just right and the disc up top for the swastika is made up of several copper discs soldered together for the appropriate thickness.

The flag was printed from an online photo and resized. The red color appears a bit faded, but that will actually work out just right. I made the rope to scale using three strands of heavy sewing thread by twisting them tightly, then I added a thin layer of good 'ol Elmer's glue all over it. I kept this new flag rope stretched out until it was completely dried. While waiting for this to dry I made small loops with the original heavy thread at the top and bottom of the flag portion that will be attached to the pole. Then, when the rope was completely dry, I ran it through the loops and mounted it on the pole. I will have to go back and paint this rope, maybe a medium tan tone, but it's pretty much complete for now.

Ok, here is the results so far. Everything seems to be in place and ready for the steps and wood work. Sorry, the flag mounted photo will appear later.

Thanks for watchin. Cheers, Ski.

|

|

|

|

Post by Dukemaddog on Apr 17, 2018 12:36:19 GMT -6

Stunning work! Just.... stunning! Far beyond my skill set; you are a true Master!

|

|

|

|

Post by JCON on Apr 17, 2018 13:02:38 GMT -6

You certainly aren't holding back with this one Bro!!! Absolutely amazing for sure!!!  |

|